Dredging is a vital process for many industries. It keeps waterways clear, helps with land reclamation, and even cleans up pollution. But to do these jobs right, you need the proper equipment. This is where finding the right dredge manufacturer becomes very important. Choosing wisely ensures your project runs smoothly and successfully.This guide will help you understand the key things to look for. We will break down important factors. This way, you can pick a top-tier dredge manufacturer that truly meets your needs. Quality, new ideas, and strong support are what truly make a difference in this field.

Understanding Your Dredging Needs: The First Step to Finding a Top Dredge Manufacturer

Before you even start looking at different machines, you need to know exactly what your project requires. Every dredging job is unique. Your specific needs will guide your choice of equipment and, by extension, your dredge manufacturer.

Project Scope & Material Type

Think about the material you need to move. Is it fine sand, sticky clay, thick silt, or even rocks? Some dredges are better for hard, compacted materials, while others excel with loose, soft sediments. Knowing your material is crucial.

Consider the size of your project. Are you cleaning a small pond, deepening a large harbor, or dealing with extensive mine tailings? The depth you need to reach and how far you need to pump the material also play a big role in selecting the right size and power of the dredge.

Site Conditions & Environmental Concerns

Where will the dredge operate? Some sites have limited access, requiring smaller, more portable machines. Others might have sensitive linings, like in wastewater treatment ponds, which demand specialized dredging equipment that won’t cause damage. Environmental regulations are also increasingly strict. A responsible dredge manufacturer will offer solutions that minimize impact, such as precise sediment removal and reduced emissions.

Types of Dredges & What Leading Dredge Manufacturers Offer

There are different kinds of dredges, each designed for specific tasks. Understanding these types will help you narrow down your search. Top dredge manufacturers usually offer a range of options to fit various applications.

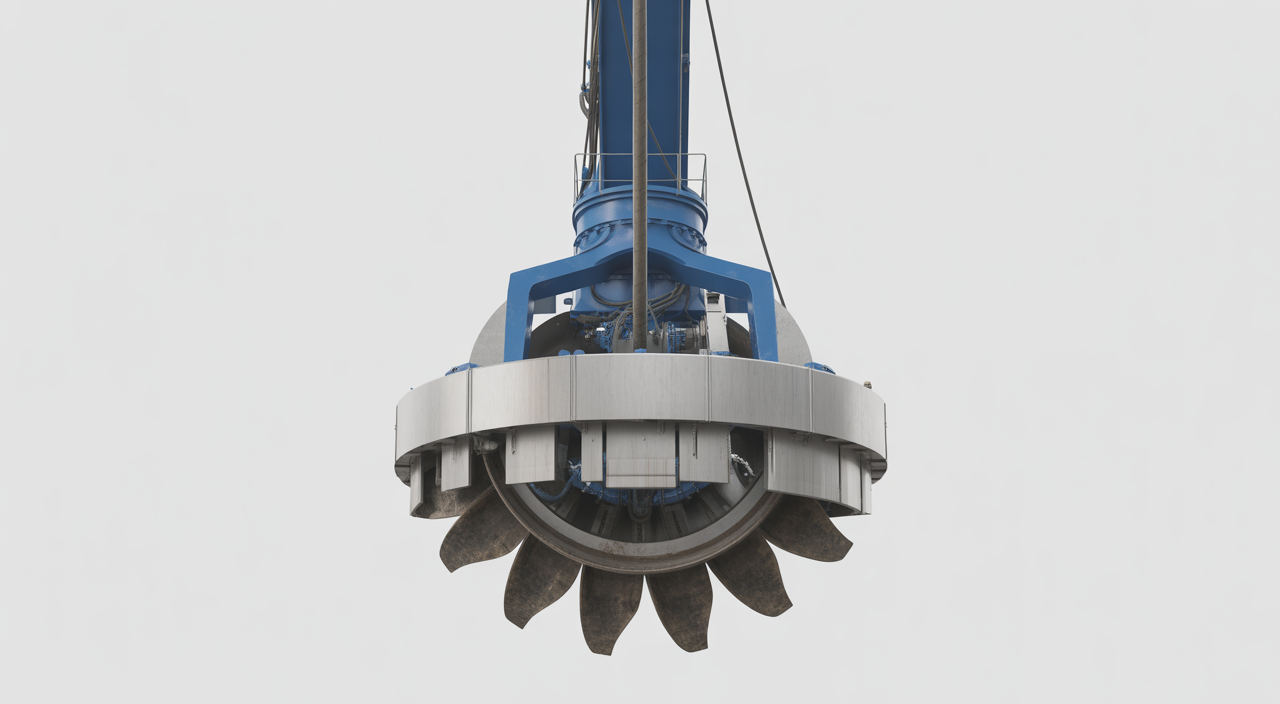

Cutter Suction Dredges (CSD)

Cutter suction dredges are workhorses for many projects. They use a rotating cutter head to break up compacted material on the seabed or river bottom. Then, a powerful pump sucks up the loosened material and sends it through a pipeline.

These dredges are excellent for sand, gravel, clay, and even some rock. When evaluating a dredge manufacturer for a CSD, look for robust cutter heads, efficient hydraulic systems, and pumps designed for high production rates. They are often used for deepening navigation channels and reclaiming land.

Hydraulic / Pump-Out Dredges

Hydraulic dredges, often called pump-out dredges, rely mainly on powerful pumps to move loose sediment. They don’t always have a cutter head. Instead, they might use agitation or just suction. They are very effective for moving large volumes of watery slurry. These are often chosen for environmental cleanups, removing soft silts, or maintaining reservoirs.

A good dredge manufacturer will focus on the efficiency of the pump and pipeline system for these types of machines. They prioritize minimizing water content and maximizing solids in the slurry pumping process.

Portable & Versatile Dredges

Some projects need more flexibility. Portable dredges can be moved easily from one site to another, sometimes even over land. Versatile dredges, like amphibious or tracked models, can operate in very shallow water or even on land next to the water. This makes them perfect for difficult terrains or projects with varying conditions.

Innovation in portable dredge systems is a key area where manufacturers distinguish themselves. Look for features that enhance mobility, ease of assembly, and adaptability to different applications, from pond cleaning to delicate environmental remediation. If you’re curious about the general processes involved, exploring how a dredge manufacturing company operates can offer valuable insights into these capabilities.

Key Factors to Evaluate When Choosing a Dredge Manufacturer

Once you understand your needs and the types of dredges available, it’s time to evaluate potential manufacturers. Not all are created equal. Here are the critical factors to consider.

Engineering & Customization Capabilities

Many projects have unique challenges. A top dredge manufacturer should offer strong engineering and design capabilities. This means they can tailor a dredge to your exact specifications. Look for companies with in-house design teams and fabrication facilities. This ensures seamless quality control from the very first sketch to the final product.

Technological Innovation & Efficiency

Modern dredging is getting smarter. Look for a dredge manufacturer that invests in new technologies. This could include automated systems, remote control options, or fuel-efficient engines. These innovations can lead to lower operating costs, greater precision, and improved safety. For those focused on environmental impact, learning about sustainable solutions for industrial waste recycling highlights the broader context of responsible industrial practices.

Durability & Build Quality

A dredge is a significant investment. You want it to last. Ask about the materials used in construction and the manufacturing standards. High-quality components and robust construction mean less downtime and a longer lifespan for your dredging equipment. This translates to better value over time.

After-Sales Support & Service

What happens after you buy the dredge? Excellent after-sales support is crucial. This includes quick access to spare parts, reliable field service technicians, and thorough operator training. A manufacturer that offers strong support ensures your operations continue without major interruptions.

Reputation & Track Record

Check the manufacturer’s history and reputation. Do they have a long track record of success? Look for client testimonials and case studies that match your project type. A well-established dredge manufacturer with a strong reputation for reliability and customer satisfaction is always a safer bet.

Total Cost of Ownership (TCO)

Don’t just look at the purchase price. Consider the total cost of owning and operating the dredge over its lifetime. This includes fuel consumption, maintenance costs, parts availability, and even potential resale value. An initially more expensive dredge might save you money in the long run if it’s more efficient and reliable.

Conclusion: Making an Informed Decision with Your Dredge Manufacturer

Choosing the right dredge and the right manufacturer is a big decision. It directly impacts your project’s success, budget, and timeline. By carefully evaluating your needs, understanding dredge types, and looking at key factors like engineering, innovation, and support, you can make an informed choice.

Remember, you’re not just buying a machine; you’re investing in a partnership. A reliable dredge manufacturer will be a partner who supports you through the entire life of your equipment. Take your time, do your research, and choose a partner that ensures efficient and effective dredging for years to come.

Frequently Asked Questions (FAQs)

What is the typical lifespan of a well-maintained dredge?

The lifespan of a dredge can vary greatly depending on its type, construction quality, and how well it’s maintained. Generally, a high-quality dredge from a reputable manufacturer, with proper maintenance and regular servicing, can last 20 to 30 years or even longer. Regular preventative maintenance, timely repairs, and appropriate operator training are key to maximizing its operational life.

How important is customization in dredge selection?

Customization is very important, especially for projects with unique conditions or specific material types. While standard models are suitable for many tasks, the ability to modify pump sizes, cutter heads, discharge distances, or add specialized instrumentation can significantly improve efficiency and effectiveness. A manufacturer with strong engineering capabilities can tailor a dredge to fit your exact operational requirements, leading to better project outcomes and a higher return on investment.